The Critical Role of WRAS in Modern Water Conservation

Water conservation has become a critical priority in modern plumbing systems, with stringent water fittings regulations ensuring efficient cold water usage while maintaining functionality. The Water Regulations Advisory Scheme (WRAS) leads these efforts in the UK, regulating flushing devices for WC pans to conserve water and safeguard plumbing systems in domestic premises, non-domestic premises, and commercial premises.

Key requirements include:

This article explores WRAS approvals, covering technical specifications, installation guidelines, and environmental benefits. Understanding WRAS approvals can certainly help you select the right toilet that complies with regulations and performs reliably on your property.

Understanding WRAS and Water Regulations

The Water Regulations Advisory Scheme serves as an independent certification body ensuring plumbing products comply with the Water Supply (Water Fittings) Regulations 1999.

WRAS plays a vital role in the approval process for various components, including flushing devices, flush drop valves, and flush outlet valves. The organization conducts rigorous performance tests and endurance tests to verify that products meet regulatory requirements.

These regulations apply to all water fittings, pipes, and appliances in premises connected to the public water supply, establishing mandatory standards for manufacturers, installers, and property owners. The regulations emerged from the growing recognition of water conservation needs as water scarcity concerns became more prominent.

WRAS approval indicates a product complies with regulations, offering assurance to consumers, installers, and Water Companies that fittings meet quality standards. The approval process includes accredited lab testing to verify compliance with requirements for non-metallic materials, mechanical performance, and water efficiency.

Applicable test code sheets provide detailed methodologies for evaluating performance.

Water Suppliers benefit from WRAS-approved products, as these fittings prevent contamination of public water supply and reduce unnecessary consumption. The approval documentation serves as evidence of compliance, which is particularly important for commercial premises where water usage is closely monitored.

Technical Specifications for WC Pan Flushing Devices

WRAS-approved WC pan flushing devices are designed to balance performance and water efficiency. A key requirement is that no flushing device connected to a WC cistern can release more than 6 litres per flush. This limit represents a major improvement over older systems, which used 9 litres or more per flush.

For dual flush systems, WRAS approvals specify that reduced flush volumes shall not exceed two-thirds of the largest flush volume. This creates a proportional relationship between full and reduced flush options, ensuring meaningful water savings while maintaining effective waste removal.

In practical terms, a dual flush toilet with a 6-litre full flush would have a reduced flush volume of no more than 4 litres. Many manufacturers optimize designs for even greater efficiency, with reduced flush volumes of 3 litres becoming common in systems utilizing innovative dual push button mechanisms.

These specifications account for diverse flushing mechanisms available in the market. Whether using a gravity-fed WC cistern, pressure-assisted mechanism, or direct pressure flushing valve with an ABS body, the same volume limitations apply.

Gravity-fed systems typically use carefully designed flush drop valves or flush WC outlet valves that meter the precise amount of water released during each flush cycle.

Flow restrictors ensure compliance with volume requirements regardless of supply pressure variations.

Modern innovative products often feature plastic bodies with precisely engineered internal components, including plastic tubes and non-metallic materials that resist corrosion and provide consistent performance at various maximum working pressures.

Backflow Prevention Requirements

Backflow prevention is a key safety requirement in WRAS approvals, protecting potable water from contamination. Regulations mandate that any pressure flushing valve connected to a supply pipe must include a backflow prevention device. This device, a permanently vented pipe interrupter, must be positioned at least 300mm above the WC pan’s spillover level.

Toilets pose a high backflow risk due to their direct contact with human waste. Without proper safeguards, negative pressure in the cold water supply could draw contaminated water from the toilet bowl into the drinking water system. WRAS-approved air gap arrangements prevent this by physically blocking the reverse flow. Water companies and suppliers prioritize compliance to ensure drinking water safety.

Backflow prevention devices vary by risk level. Single-check valves provide basic protection for low-risk scenarios, while Double Check Valves add security in medium-risk applications. For high-risk situations, such as WC pans, air gap systems are mandatory. Vacuum breakers offer another layer of protection, introducing air into the system to counteract negative pressure.

Cistern-fed systems typically prevent backflow through an air gap between the inlet valve and the maximum water level. In direct pressure flushing systems, additional devices like atmospheric vacuum breakers are required to prevent contamination.

Backflow testing simulates worst-case conditions to ensure these mechanisms work effectively. Proper documentation of backflow protection is a crucial part of WRAS approval.

Additional backflow testing typically involves creating worst-case scenario conditions to verify that the backflow prevention mechanism functions effectively. Evidence of backflow protection must be thoroughly documented as part of the approval documentation.

Installation and Marking Requirements

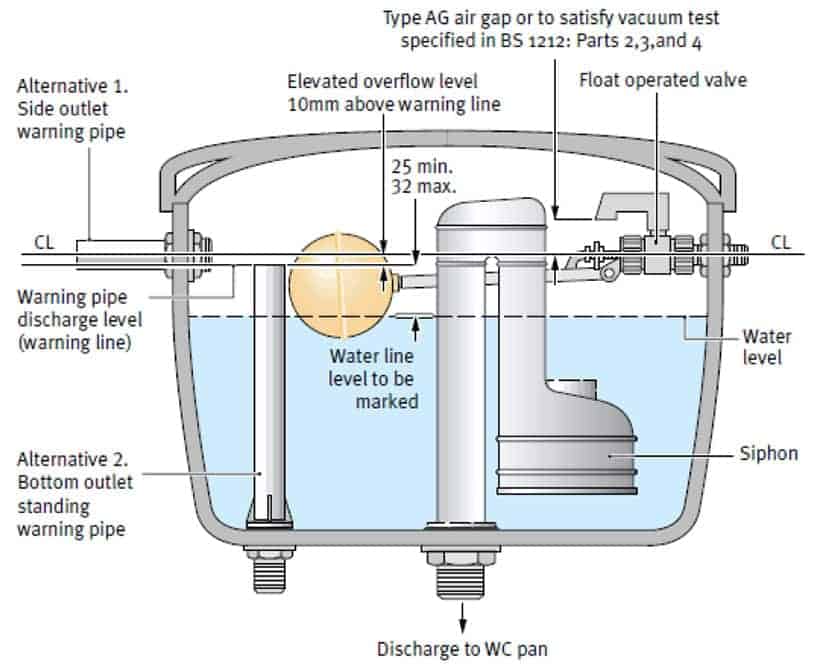

Proper installation and marking of WC flushing devices are essential for functionality, user clarity, and regulatory compliance. Each cistern must have a permanent internal line showing the intended flush volume. This helps installers set the correct level, allows maintenance staff to check adjustments, and lets inspectors confirm compliance.

Dual flush systems require extra markings. The cistern must include a clearly visible way to activate each flush option, along with simple instructions. Without this, users may default to the full flush, reducing water-saving benefits.

WRAS approvals also cover overflow mechanisms. Every flushing cistern must include an internal overflow or a similar device. Many modern cisterns use adjustable or circular overflows that visibly signal overflow conditions, helping users catch issues early and avoid water waste.

Installation height also matters—especially for backflow prevention. Pressure flushing valves must include devices placed at least 300mm above the WC pan’s spillover level. Isolation valves are recommended to allow maintenance without shutting off the full cold water supply.

Flow rate is another key factor. Pressure flushing valves can only be used where the flow rate is at least 1.2 litres per second. Differences in building pressure zones must be accounted for, as they affect performance. Maximum working pressures must not be exceeded to protect parts like plastic tubes, bodies, and hose assemblies from damage.

Water Conservation and Environmental Impact

WRAS approvals for flushing devices mark a major shift in water conservation for modern plumbing. Before these regulations, most WC flushes used 9 litres or more. The move to a 6-litre maximum has cut water use by at least 33% and by over 50% compared to older models—saving billions of litres annually.

The benefits go beyond just water. Pumping, treating, and delivering cold water for drinking systems uses energy. Lower flush volumes reduce that demand, helping cut carbon emissions. In areas with water scarcity, this efficiency supports more reliable access during dry periods.

Dual flush systems boost savings even further. Around 80% of flushes are for liquid waste, which the reduced flush handles well. With a typical setup of 6 litres for full flush and 4 litres for reduced, average use drops to about 4.4 litres per flush—another 27% drop compared to standard single flush systems.

These savings pay off. Households and businesses see lower water bills while Water Companies cut treatment costs and ease pressure on infrastructure.

Some manufacturers now offer models that go beyond WRAS minimums, using just 4.5 litres for full flushes and 2.5 litres for reduced. Modern tapware also improves efficiency. Many include flow restrictors and advanced valve designs to perform reliably under different pressures.

Water-saving features are spreading to other fixtures, too. Tap assemblies with aerators can cut use by up to 50% over traditional taps. Thermostatic shower valves reduce waste by keeping the temperature steady without manual adjustments. Combined with efficient WC cisterns, these products offer full-system water efficiency for both cold and hot water systems.

Compliance and Testing

WRAS approval requires thorough testing to ensure products meet water fittings regulations. Tests cover flush volume, backflow prevention, durability, and correct marking using standard procedures and official test code sheets.

Flush volume tests verify that single flushes don’t exceed 6 litres and that reduced flushes stay below two-thirds of the full volume. These tests run multiple flush cycles under different water pressures to confirm consistent performance. Flow control is also checked to make sure pressure changes don’t affect the outcome.

Durability tests put flushing components through thousands of cycles. Key parts like flush valves, drop valves, and push button assemblies are examined closely, since wear can affect water use. The goal is to ensure long-term water savings.

Backflow prevention is tested to confirm the protection of drinking water. For pressure flushing valves, this includes checking that the pipe interrupter is set at least 300mm above the WC pan spillover level. Single-check valves, Double Check Valves, and vacuum valves are tested based on their specific designs and risk levels.

Material testing focuses on parts made from plastics and other non-metallic materials in contact with drinking water. Washers, tubes, and valves must show both durability and safe compatibility with potable water. Items like air inlet valves, isolation valves, and drain valves must hold up under maximum pressure.

Failure to pass WRAS testing has serious consequences. Water Companies can block the connection of properties with non-compliant fittings. Installers may face liability if unapproved products cause damage or contamination. This creates strong incentives for manufacturers to meet testing standards and secure WRAS approval.

Case Studies and Examples

WRAS-approved flushing devices deliver both practical benefits and significant water savings.

A major hotel chain upgraded 3,000 outdated 9-litre toilets to dual-flush systems with a 6-litre full flush and a 3-litre reduced flush, operated via dual push-button assemblies. The new WC cisterns featured plastic bodies and internal overflow mechanisms. Post-installation monitoring showed a 47% water savings—15 million litres annually—achieving full ROI within 18 months with no impact on user experience.

In the public sector, a hospital installed WRAS-approved pressure flushing valves with advanced backflow prevention. The system included:

Innovative designs like Villeroy & Boch’s TwistFlush system, which operates with a 4.5-litre full flush and 3-litre reduced flush, demonstrate how water efficiency can be dramatically improved without sacrificing performance.

The TwistFlush harnesses the power of a water vortex to provide thorough and hygienic cleaning while using significantly less water than conventional toilets, saving families up to 19,700 litres of water annually.

WRAS approvals have also enhanced flexible hose assemblies and combination tap assemblies. Wash basin products now include self-cancelling diverter mechanisms that automatically reset after use. Manual diverters allow users to control water flow, while automatic diverters help conserve water when taps are left unattended.

Wrapping Up

WRAS approvals for flushing devices provide a vital framework for ensuring water efficiency, safety, and regulatory compliance in modern plumbing systems. Key requirements—such as a maximum 6-litre single flush and a reduced flush limited to two-thirds of the full volume—have significantly improved water conservation without sacrificing functionality.

Water fittings regulations have evolved from basic volume restrictions into a comprehensive framework covering various flushing device components, including WC drop valves, flush outlet valves, push button assemblies, and internal overflow mechanisms. This shift reflects a growing awareness of water as a critical resource.

For manufacturers, installers, and property owners, understanding WRAS requirements is essential for compliance and maximizing water-efficient technology. Water companies and suppliers depend on these standards to uphold drinking water system integrity through effective backflow prevention.

The integration of components—from plastic bodies and tubes to combination fittings and flow restrictors—demonstrates the complexity of modern plumbing systems. Whether for homes or commercial properties, selecting and installing compliant products ensures long-term performance and regulatory adherence.

From wash basins and WC cisterns to shower valves and bidet appliances, WRAS-approved solutions promote water conservation and safety across the built environment.

By setting clear standards, WRAS approvals show how regulation can drive environmental benefits while preserving essential functionality. As water scarcity becomes a global concern, these principles offer valuable guidance for sustainable resource management.